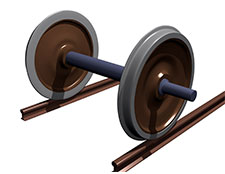

Industrial Parts Axle Washing and Drying Machine Manufacturers & Exporters in Pune, India.

Machinery Parts

The Axle Washing and Drying Machine manufactured by Nexon Automation is designed to scrub the railway axles clean and then dry them. The features include hot water spray washing, ambient and hot air-drying system, and a gantry for automatic loading and unloading of the product to satisfy the hygiene demand characteristic of the rail and car industries.

Railway axles Washing & Drying Machine Key Features:

- Gantry Loading and Unloading: It is used in the automatic transferring and lifting of axles which reduces dependency on man and also improves accuracy of the gantry system.

- Rotary Washing System: In washing, all the axles turn in order to be exposed to the solution for adequate washing without missing a part in the system.

- Hot Water Spray Wash: High pressure hot water combined with alkali solution is saturating the bearings in order to eliminate the grease, oil and other contaminants from the axles.

- High-Pressure Air Blower System: Our high-pressure air blower (650 CFM at 150 mbar) provides 650 CFM at 150 mbar, this tool is 70-80% efficient compared with common pressure air blower, therefore reasonable price and environmental protection.

- Hot Air Drying: Air temperature of 90-120 °C provides through the drying of axles without rust and further corrosion.

- Heavy-Duty Stainless Steel Construction: The machine is made of 304 grading steel for improved corrosion and durability when used in the industrial context.

Industrial Parts Washer for Axles Machine Process Flow:

- Loading: On this gantry system the axle is transferred to the washing chamber where it will be firmly fixed in a percolated position.

- Washing: High pressure hot water mixed with an alkaline solution at the temperature of 65°C is supplied through stationary carbide nozzles. It revolves round the axle for proper cleaning of the technologies on each surface they come into contact with.

- Air Blow Drying (Ambient): The system initiates high velocity air blowers that take fresh air to blow away most of the water from the axle.

- Hot Air Drying: Final ‘bake out’ of the assembly or component The hot air is applied at temperature of 90-120°C to evaporate any remaining moisture on the axle.

- Unloading: After cleaning and drying phases are accomplished, the gantry system moves the axle toward the unloading zone.

Additional Features:

- Filtration System: The machine comes with square bag filters of 150 microns and inline housing filters with a 10 micron rating to ensure the quality of the cleaning solution.

- Oil Skimmer: A disc-type oil skimmer is incorporated in the machine with a stool grinder to help eliminate oil from the cleaning solution, which is essential.

- Compact Paper Band Filter: This additional filter makes sure that it filters particles as small as 50 microns.

- Air Knife Drying System: The air knife drying system does not utilize compressed air to impose the water carryover while reducing energy consumption through two different methods of operation that may remove 80-90% water content from the process.

- Mist Collector: The mist collector sits directly above the chamber, removing fumes while providing a safe and sufficiently clean environment for the employees.

- PLC Control System: All the wash and dry programs are governed through a Programmable Logic Control, which provides variability of cycles and auto control for the operation of the machines.

Applications:

- Railways: Using for cleaning railway axles with high cleanliness standard before practicing further steps like processing or maintenance.

- Automotive Industry: Best used to clean large automobile parts including axles and shafts that need to be cleaned before they can be assembled or repaired.

Why Nexon’s Axle Washing and Drying Machine for Your Automobile Needs?

- Automated Precision: The gantry system is used for definite loading and unloading, which decreases many manual operations and increases the performance rate.

- Thorough Cleaning: High pressure washing and uniform rotation to get rid of accumulated dirt and debris perfectly clean surfaces of the axle.

- Energy Efficient: Some of these features include an air knife drying system and ambient air blowers to ensure the machine avails optimal energy usage while delivering great results.

- Robust Construction: Made from high steel material, it is suitable for use in industries where rough working conditions are observed and this serve the user for a very long time.